Next, a path is created for the foot to follow. The path is generated

from one of four stride types as defined below:

StrideTypes.MOVE_FORWARD

StrideTypes.MOVE_BACKWARD

StrideTypes.ROTATE_CW

StrideTypes.ROTATE_CCW

The create_foot_path function returns a path represented by lists of

discrete points. These points are defined in rectangular coordinates (x,

y, z) for stride types MOVE_FORWARD and MOVE_BACKWARD, and in

polar coordinates (θ, ρ, z) for stride types ROTATE_CW and ROTATE_CCW.

% Create relative paths

[lift_path, drag_path] = create_foot_path(STRIDE_TYPE, FULL_STRIDE_LENGTH, FULL_STRIDE_ARC_LENGTH,

ROBOT_RADIUS, STEP_HEIGHT, FULL_STRIDE_TIME, TIME_DELTA);

The returned path is divided into two parts, a lift_path and

a drag_path. The lift_path consists of relative

coordinates that move the foot along a parabolic curve in the z direction,

to lift it off the ground and take a step. The drag_path

contains the relative coordinates required to drag the foot along

the ground, which returns the foot back to its original position

and creates the necessary friction to move the robot. Opposite pairs of

feet on the robot alternate between the lift and drag paths, which creates

the overall walking motion.

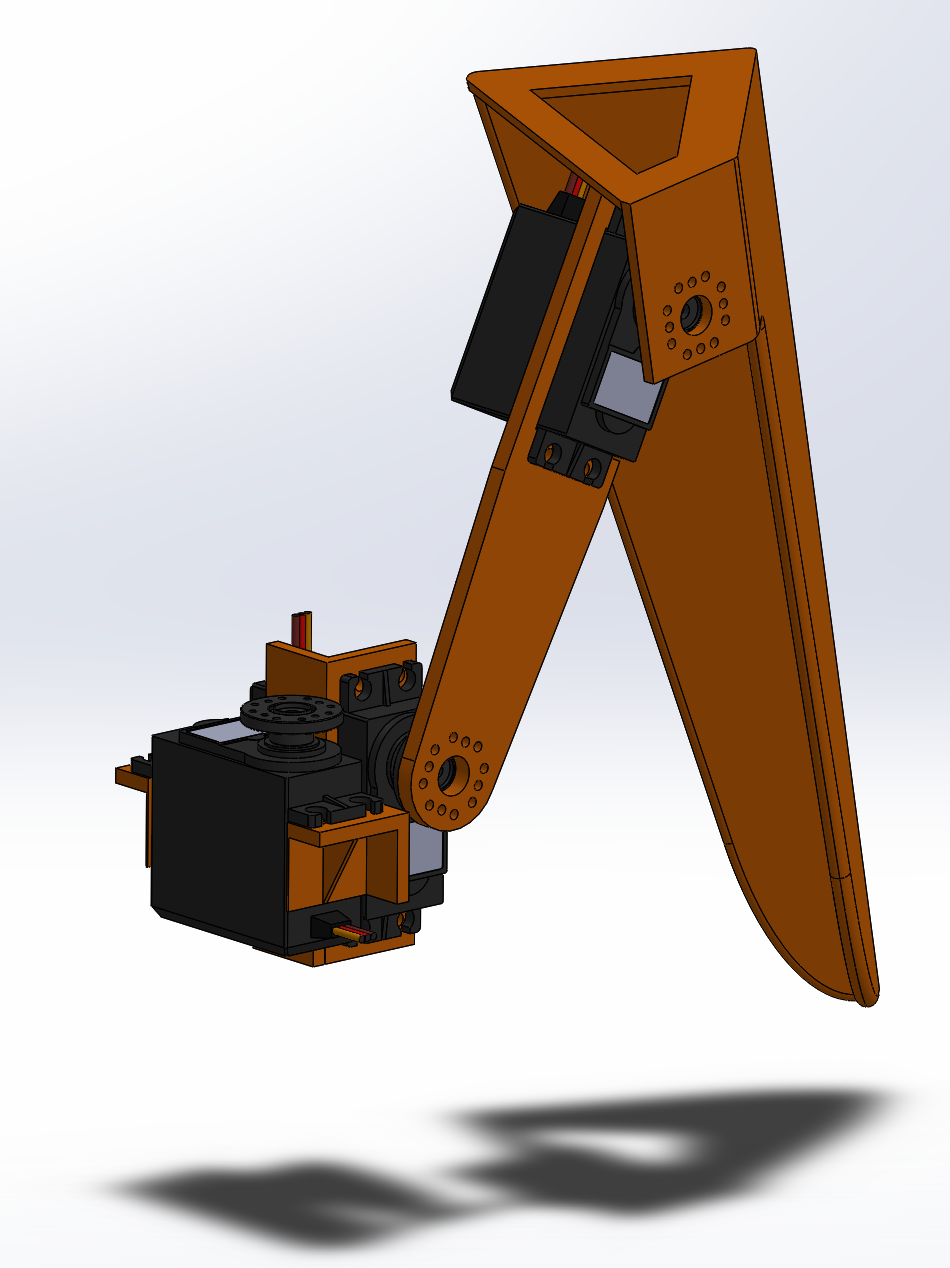

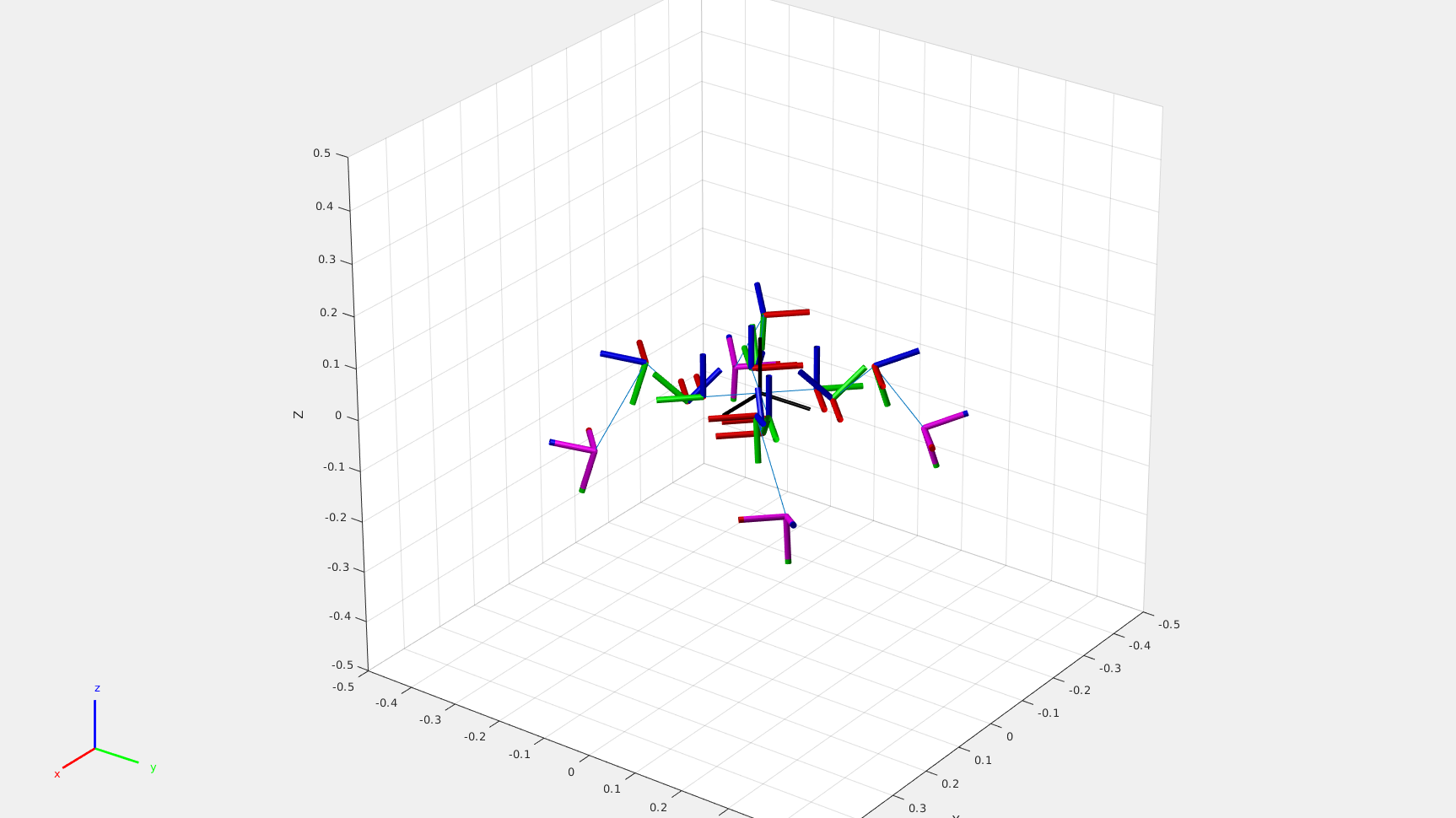

After calculating the ideal path for each foot to follow, the script

applies an inverse kinematics solver at each point in the path. Inverse

kinematics is the process of computing the joint angles in some chain of

rigid bodies required to place some end effector at a desired position and/

or orientation. In this case, the chain of bodies is the robot leg, the

joints are located at the servo motors, and the end effector is the foot. The

code snippet

which runs the inverse kinematics solver is shown below.

% Inverse Kinematics

q0 = homeConfiguration(robot);

num_dof = length(q0);

num_timesteps_per_path = size(lift_path, 1);

qs = zeros(NUM_CYCLES*2*num_timesteps_per_path, num_dof);

ik = robotics.InverseKinematics('RigidBodyTree', robot);

weights = [0, 0, 0, 1, 1, 1];

for i = 1:NUM_CYCLES

% First half-cycle: lift legs 1 and 3

foot1_start_pos = get_pos(robot, q0, 'foot1');

foot2_start_pos = get_pos(robot, q0, 'foot2');

foot3_start_pos = get_pos(robot, q0, 'foot3');

foot4_start_pos = get_pos(robot, q0, 'foot4');

q_init = q0;

for j = 1:num_timesteps_per_path

% Define destination points for each foot

if STRIDE_TYPE == StrideTypes.MOVE_FORWARD || STRIDE_TYPE == StrideTypes.MOVE_BACKWARD

% Rectangular coordinates

foot1_dest_pos = lift_path(j,:) + foot1_start_pos;

foot2_dest_pos = drag_path(j,:) + foot2_start_pos;

foot3_dest_pos = lift_path(j,:) + foot3_start_pos;

foot4_dest_pos = drag_path(j,:) + foot4_start_pos;

else

% Cylindrical coordinates

foot1_dest_pos = pol_plus_cart(lift_path(j,:), foot1_start_pos);

foot2_dest_pos = pol_plus_cart(drag_path(j,:), foot2_start_pos);

foot3_dest_pos = pol_plus_cart(lift_path(j,:), foot3_start_pos);

foot4_dest_pos = pol_plus_cart(drag_path(j,:), foot4_start_pos);

end

% Run IK for each foot

q_sol1 = ik('foot1', trvec2tform(foot1_dest_pos), weights, q_init); % indices 1:3 are relevant to foot1

q_sol2 = ik('foot2', trvec2tform(foot2_dest_pos), weights, q_init); % indices 4:6 are relevant to foot2

q_sol3 = ik('foot3', trvec2tform(foot3_dest_pos), weights, q_init); % indices 7:9 are relevant to foot3

q_sol4 = ik('foot4', trvec2tform(foot4_dest_pos), weights, q_init); % indices 10:12 are relevant to foot4

% Add solution to the qs solution matrix

q_sol = [q_sol1(1:3), q_sol2(4:6), q_sol3(7:9), q_sol4(10:12)];

idx = 2*num_timesteps_per_path*(i-1)+j;

qs(idx,:) = q_sol;

q_init = q_sol;

end

% Second half-cycle: lift legs 2 and 4

foot1_start_pos = get_pos(robot, q_init, 'foot1');

foot2_start_pos = get_pos(robot, q_init, 'foot2');

foot3_start_pos = get_pos(robot, q_init, 'foot3');

foot4_start_pos = get_pos(robot, q_init, 'foot4');

for j = 1:num_timesteps_per_path

% Define destination points for each foot

if STRIDE_TYPE == StrideTypes.MOVE_FORWARD || STRIDE_TYPE == StrideTypes.MOVE_BACKWARD

% Rectangular coordinates

foot1_dest_pos = drag_path(j,:) + foot1_start_pos;

foot2_dest_pos = lift_path(j,:) + foot2_start_pos;

foot3_dest_pos = drag_path(j,:) + foot3_start_pos;

foot4_dest_pos = lift_path(j,:) + foot4_start_pos;

else

% Cylindrical coordinates

foot1_dest_pos = pol_plus_cart(drag_path(j,:), foot1_start_pos);

foot2_dest_pos = pol_plus_cart(lift_path(j,:), foot2_start_pos);

foot3_dest_pos = pol_plus_cart(drag_path(j,:), foot3_start_pos);

foot4_dest_pos = pol_plus_cart(lift_path(j,:), foot4_start_pos);

end

% Run IK for each foot

q_sol1 = ik('foot1', trvec2tform(foot1_dest_pos), weights, q_init); % indices 1:3 are relevant to foot1

q_sol2 = ik('foot2', trvec2tform(foot2_dest_pos), weights, q_init); % indices 4:6 are relevant to foot2

q_sol3 = ik('foot3', trvec2tform(foot3_dest_pos), weights, q_init); % indices 7:9 are relevant to foot3

q_sol4 = ik('foot4', trvec2tform(foot4_dest_pos), weights, q_init); % indices 10:12 are relevant to foot4

% Add solution to the qs solution matrix

q_sol = [q_sol1(1:3), q_sol2(4:6), q_sol3(7:9), q_sol4(10:12)];

idx = 2*num_timesteps_per_path*(i-1)+j+num_timesteps_per_path;

qs(idx,:) = q_sol;

q_init = q_sol;

end

end

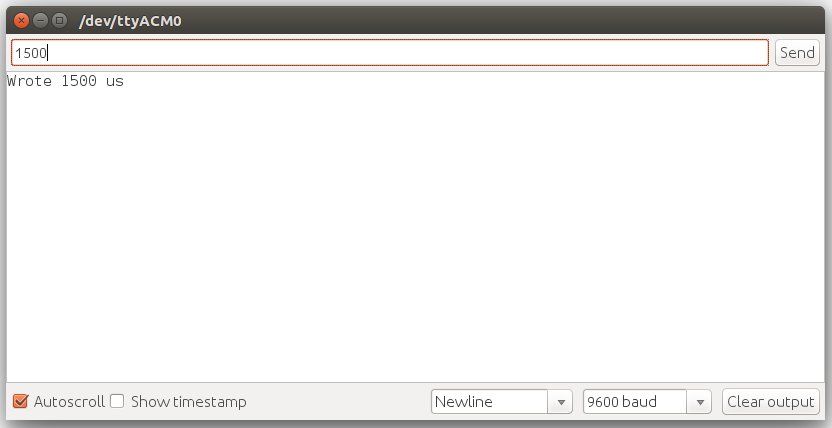

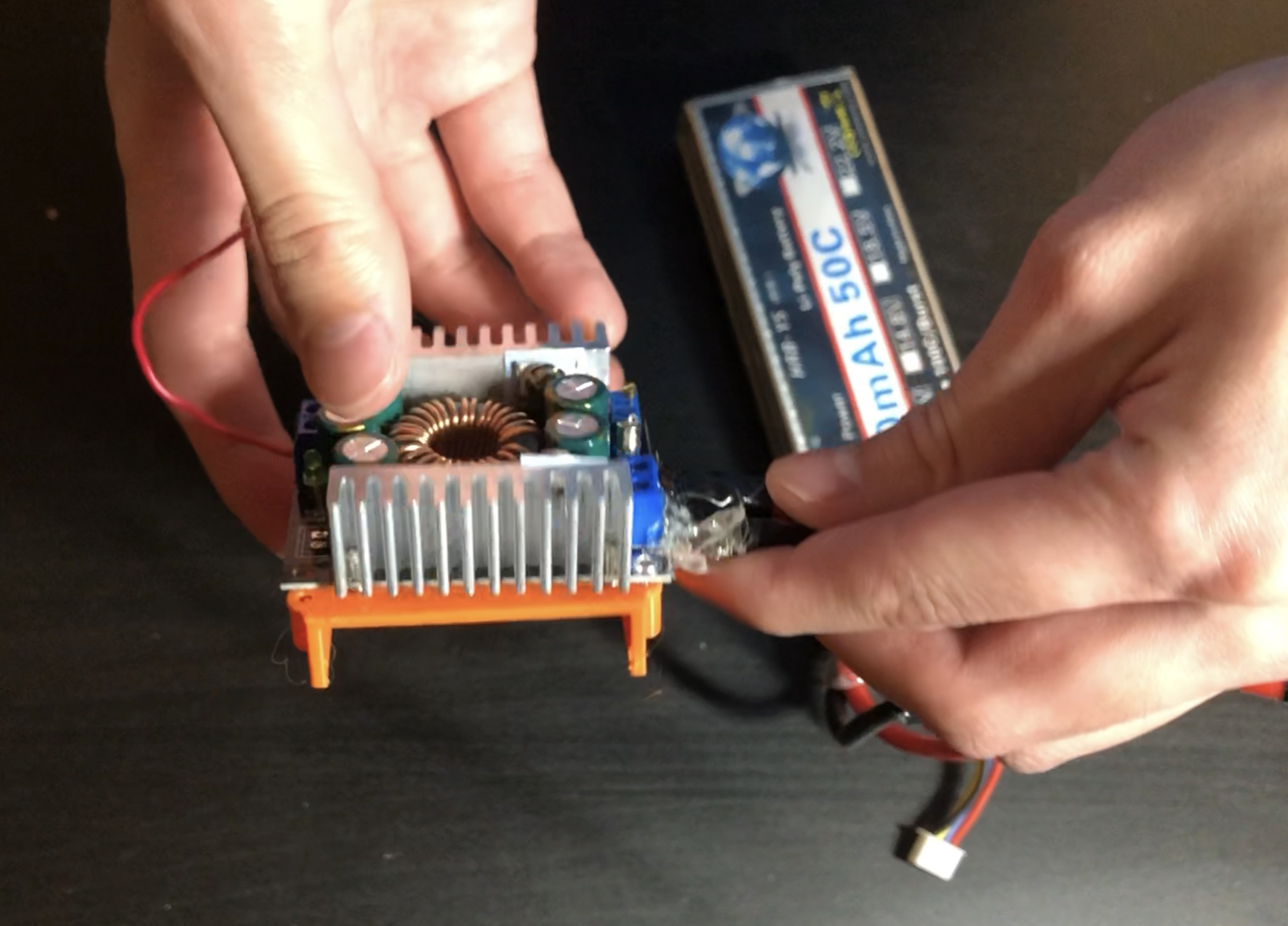

The last section of the script exports the joint angles to a CSV file,

which can then be copied into the code that runs on the Arduino. Some

conversion is required to transform the joint angles from the global

reference frame to the local servo reference frame.

function save_qs_to_file(qs)

% Convert from rad to deg

qs = rad2deg(qs);

% Copy initial angles to the beginning

q_init = qs(end,:);

qs = [q_init; qs];

% Convert to servo angle reference frame

% Set all angles to zero-referenced

qs = qs - qs(1,:);

% Reverse directions of joint angles as needed

qs(:,1) = qs(:,1)*-1;

qs(:,4) = qs(:,4)*-1;

qs(:,7) = qs(:,7)*-1;

qs(:,10) = qs(:,10)*-1;

% Add joint angle offsets

qs(:,1) = qs(:,1)+90;

qs(:,2) = qs(:,2)+90;

qs(:,3) = qs(:,3)+225+q_init(3);

qs(:,4) = qs(:,4)+90;

qs(:,5) = qs(:,5)+90;

qs(:,6) = qs(:,6)+225+q_init(6);

qs(:,7) = qs(:,7)+90;

qs(:,8) = qs(:,8)+90;

qs(:,9) = qs(:,9)+225+q_init(9);

qs(:,10) = qs(:,10)+90;

qs(:,11) = qs(:,11)+90;

qs(:,12) = qs(:,12)+225+q_init(12);

% Round to nearest integer

qs = round(qs);

writematrix(qs, 'temp.csv');

end

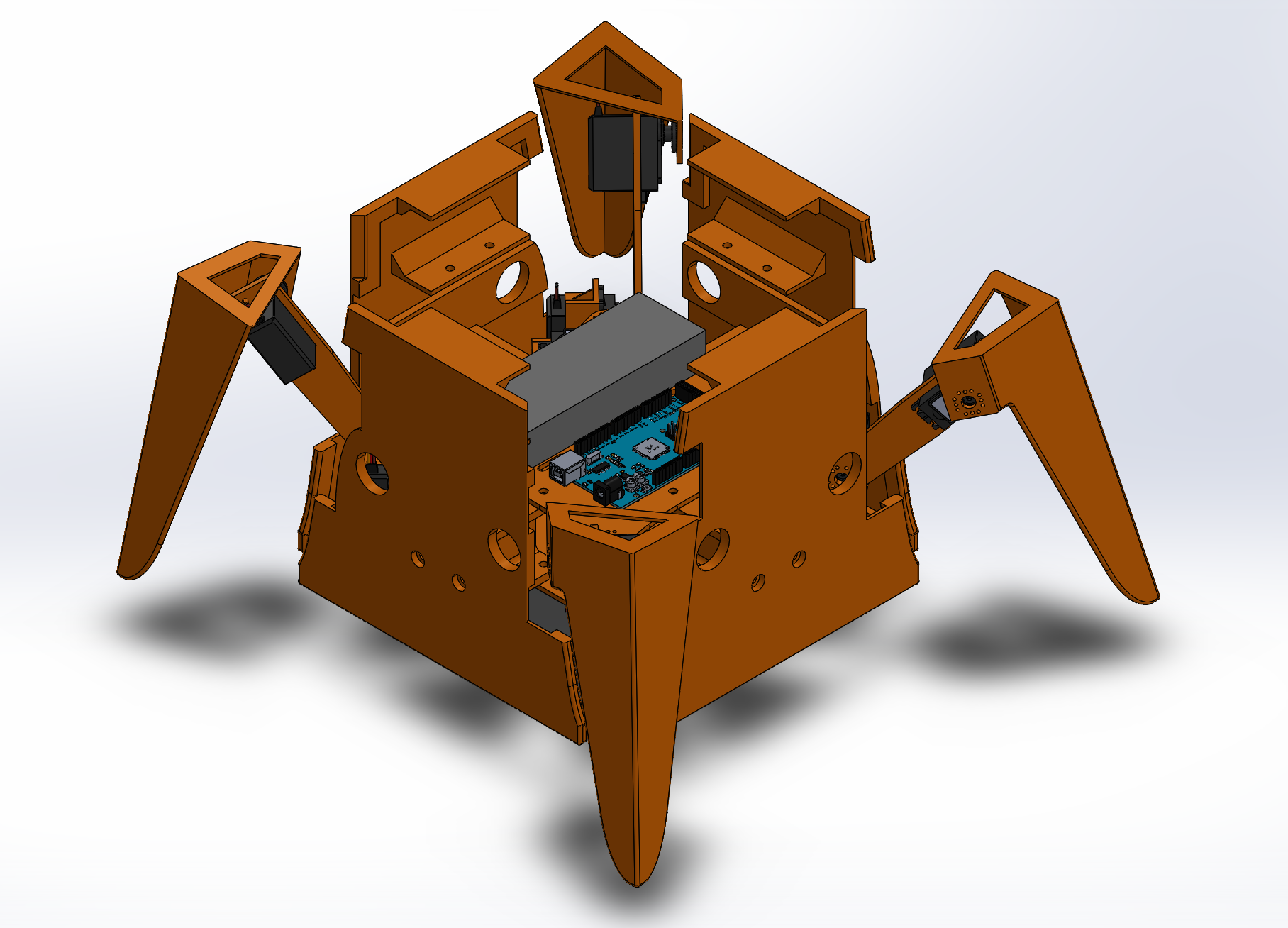

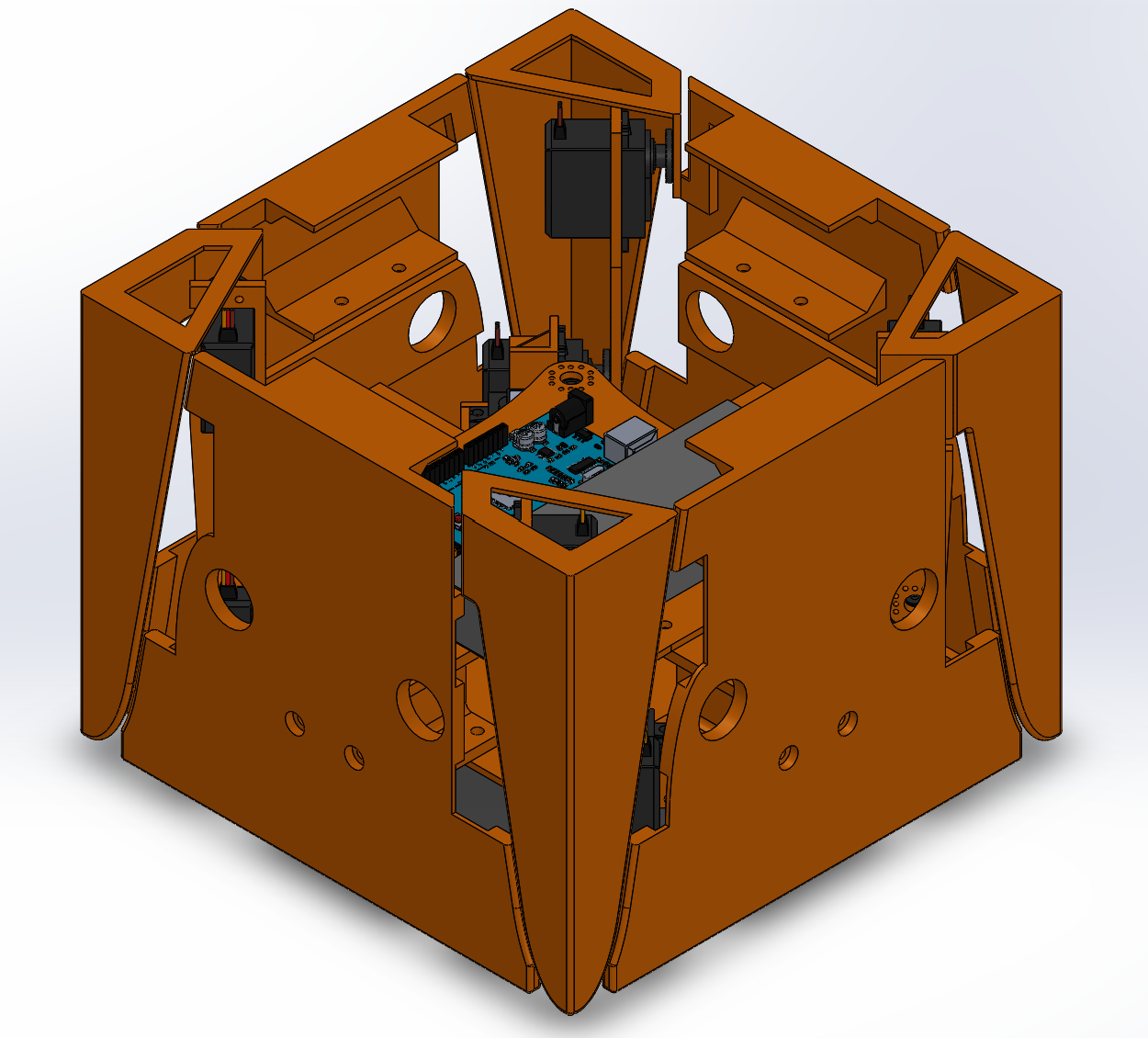

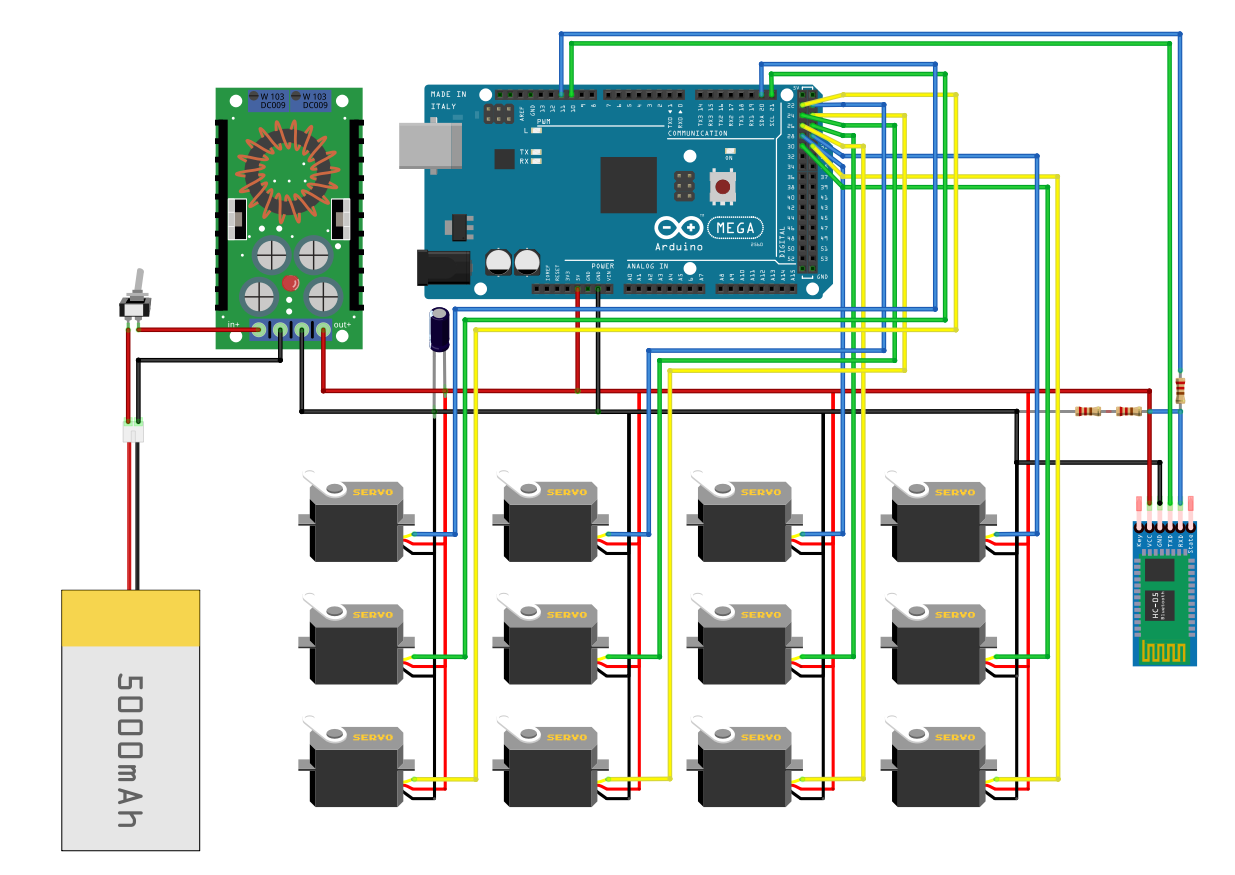

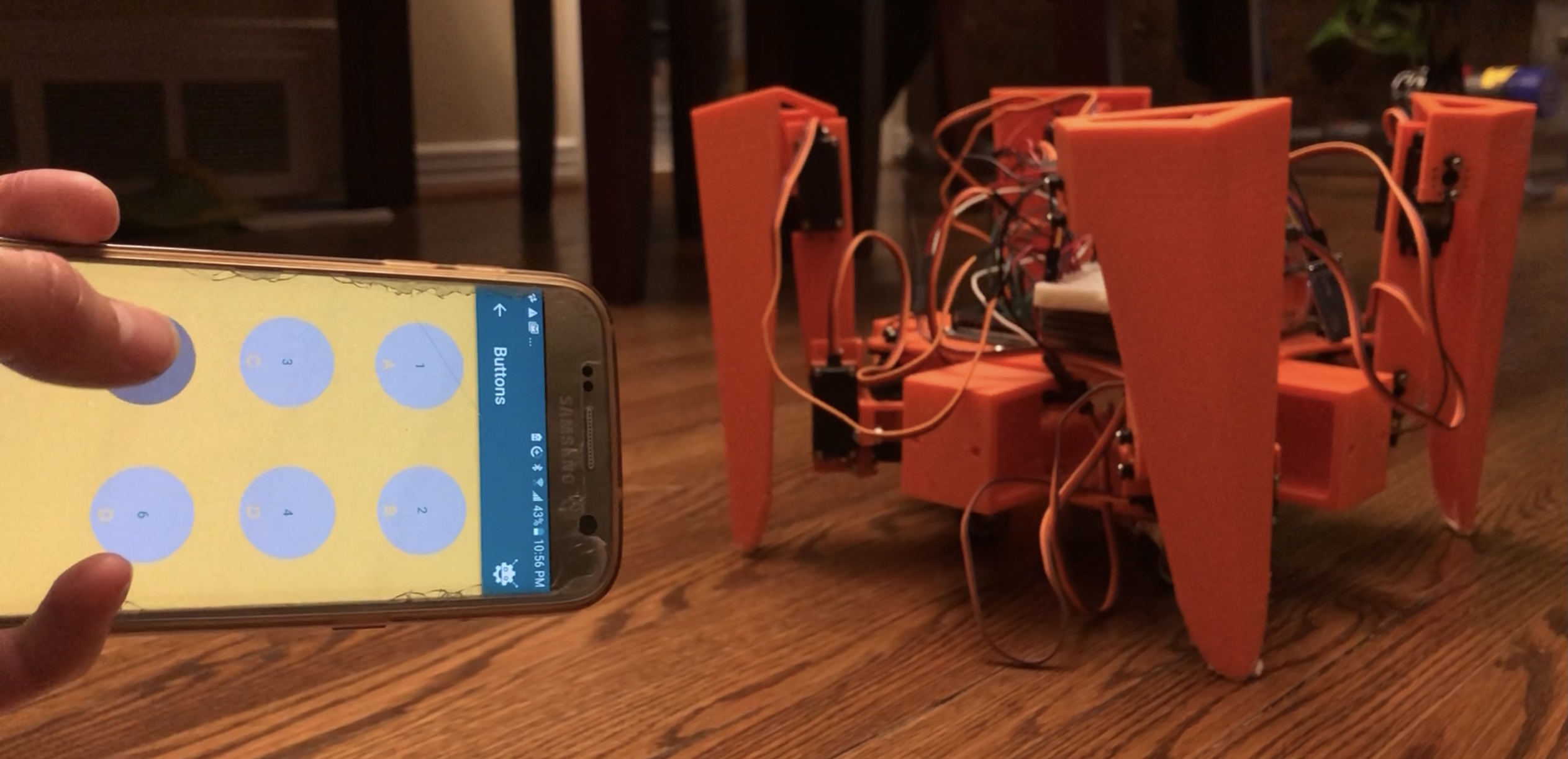

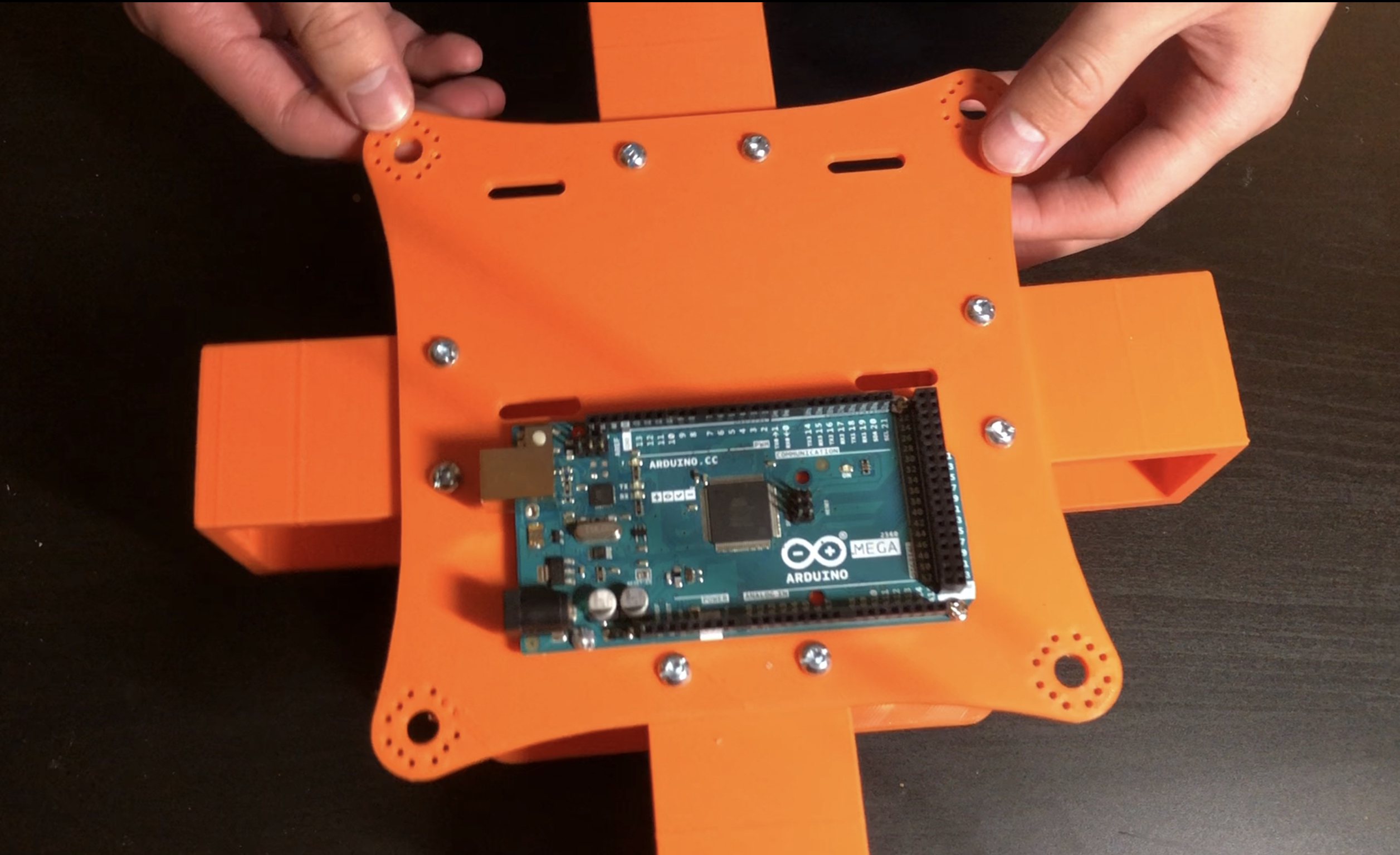

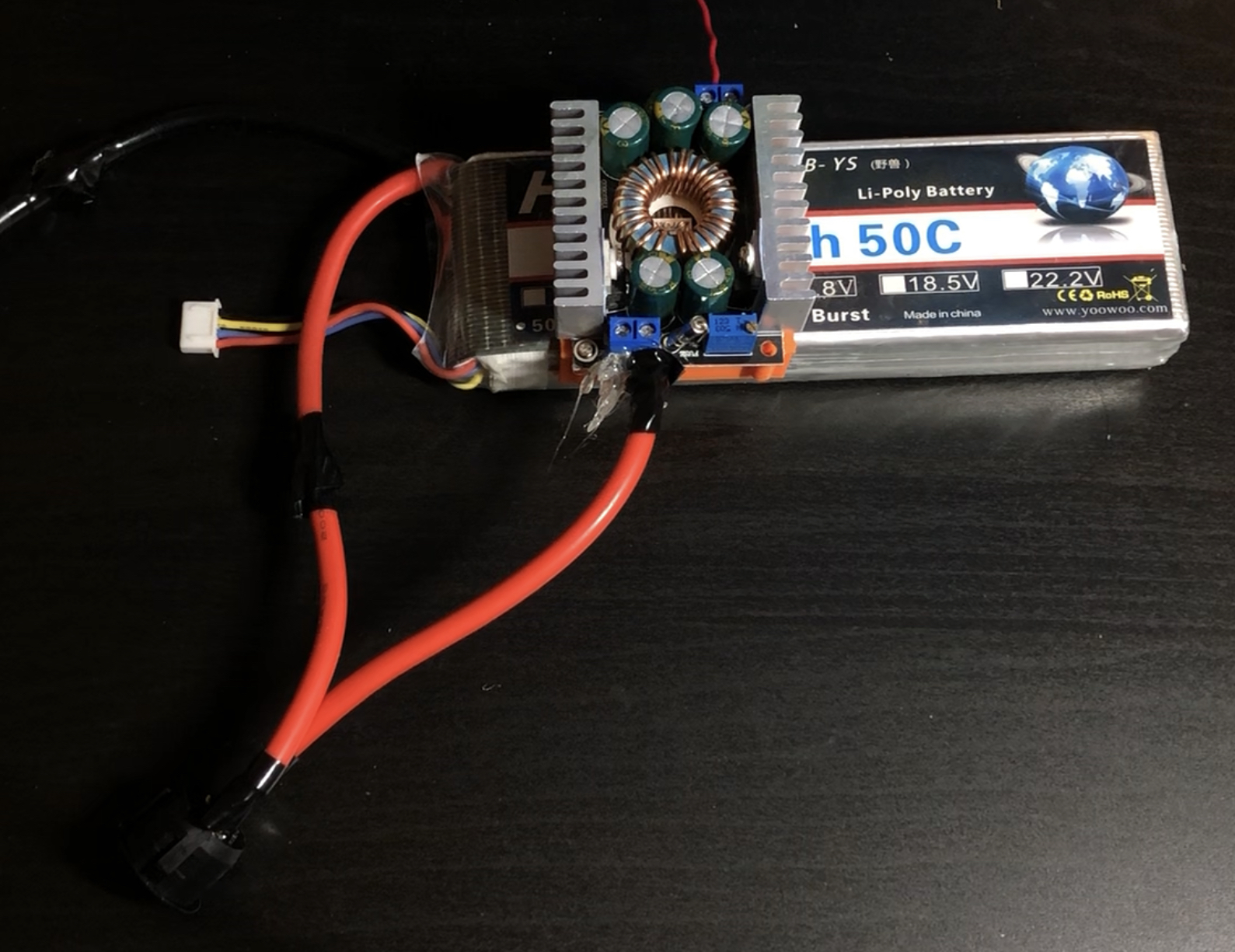

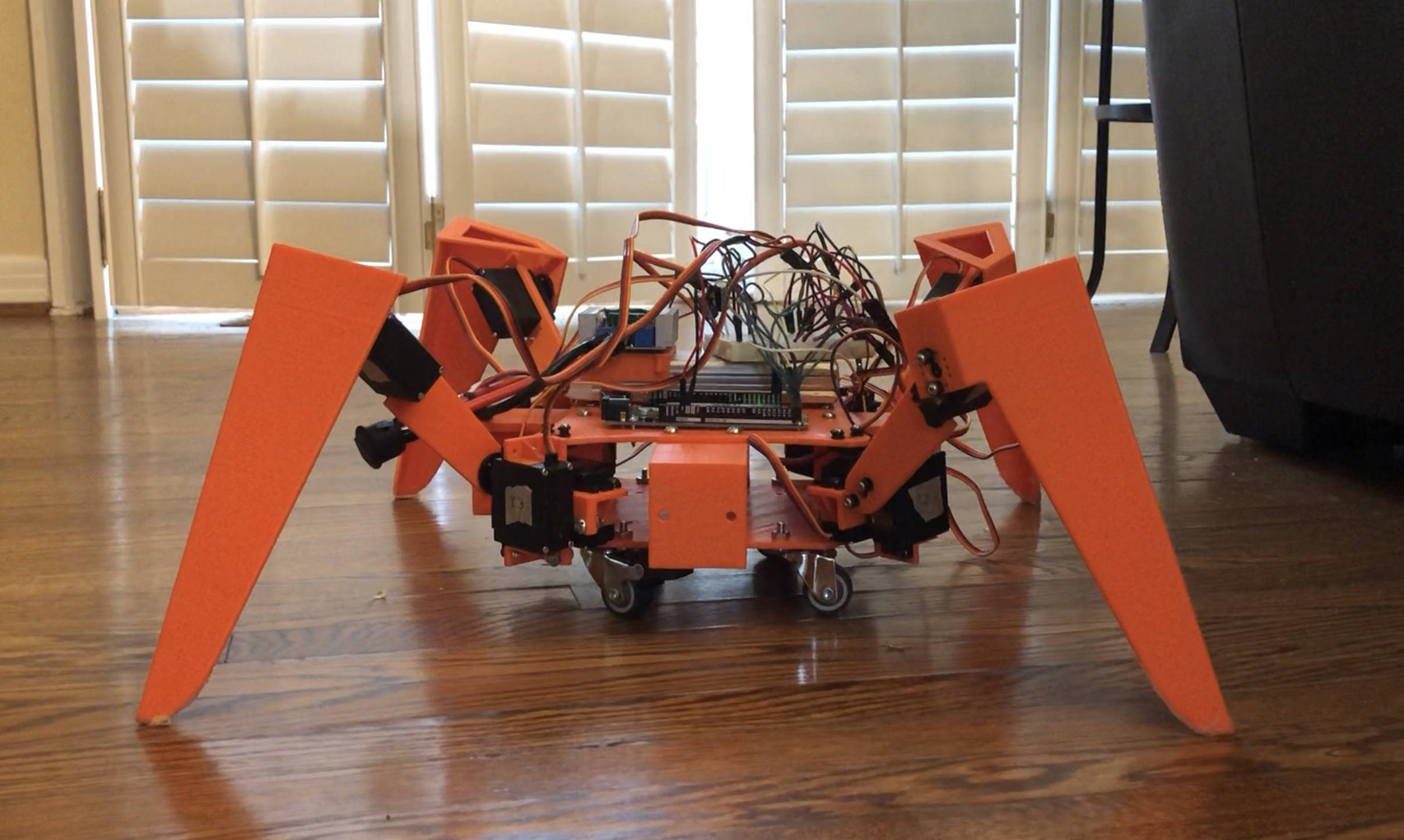

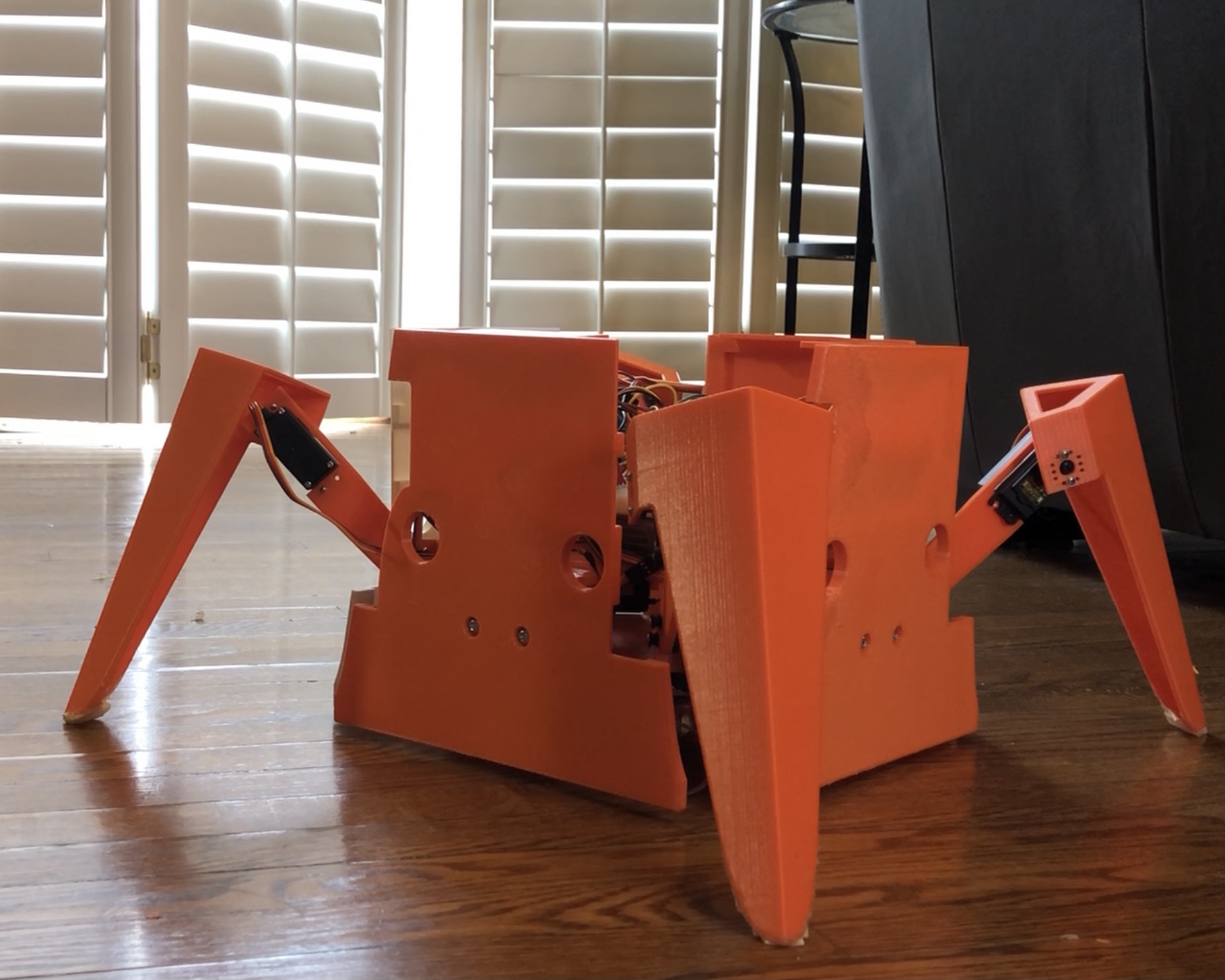

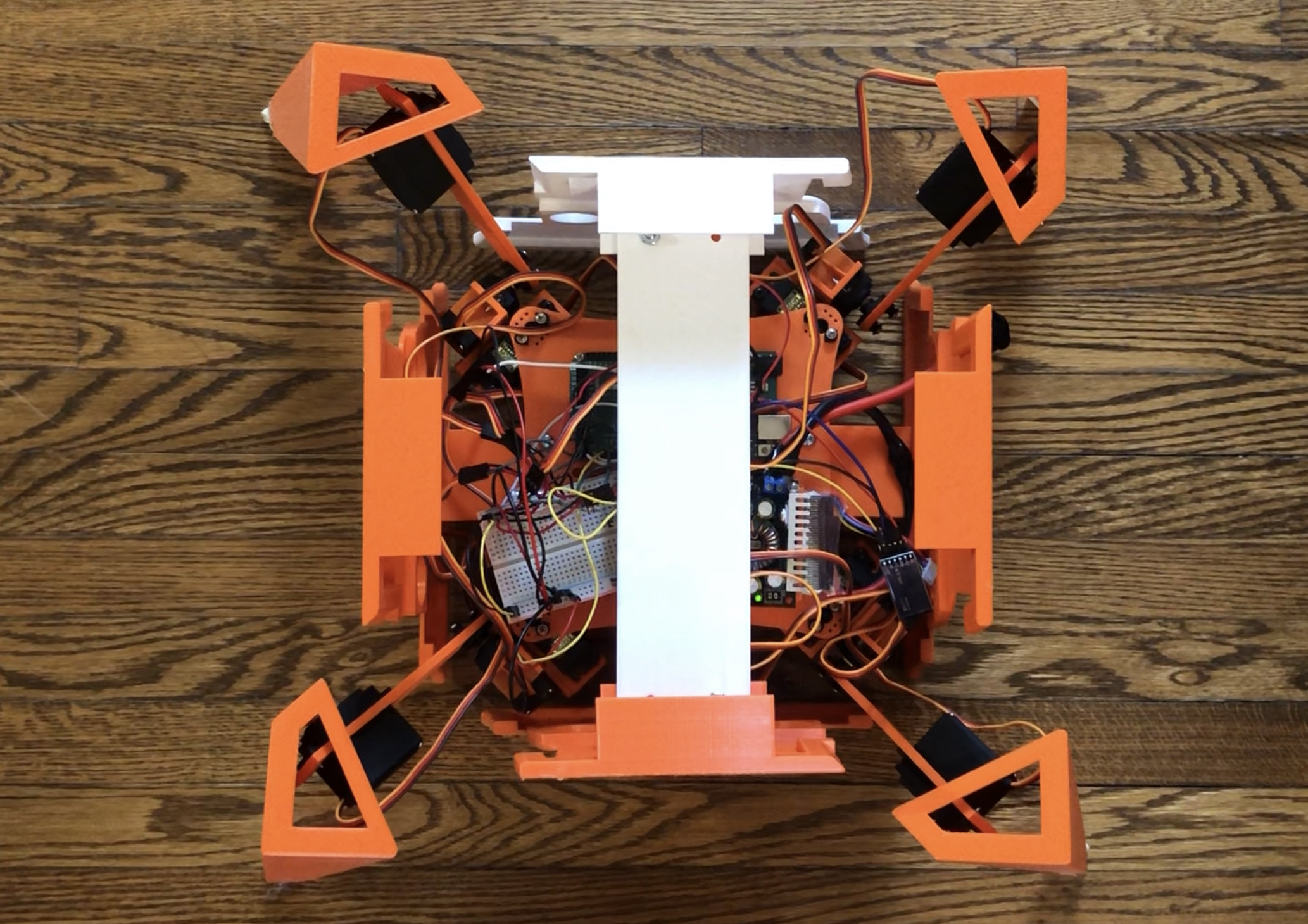

The main code that runs on the Arduino is located

here,

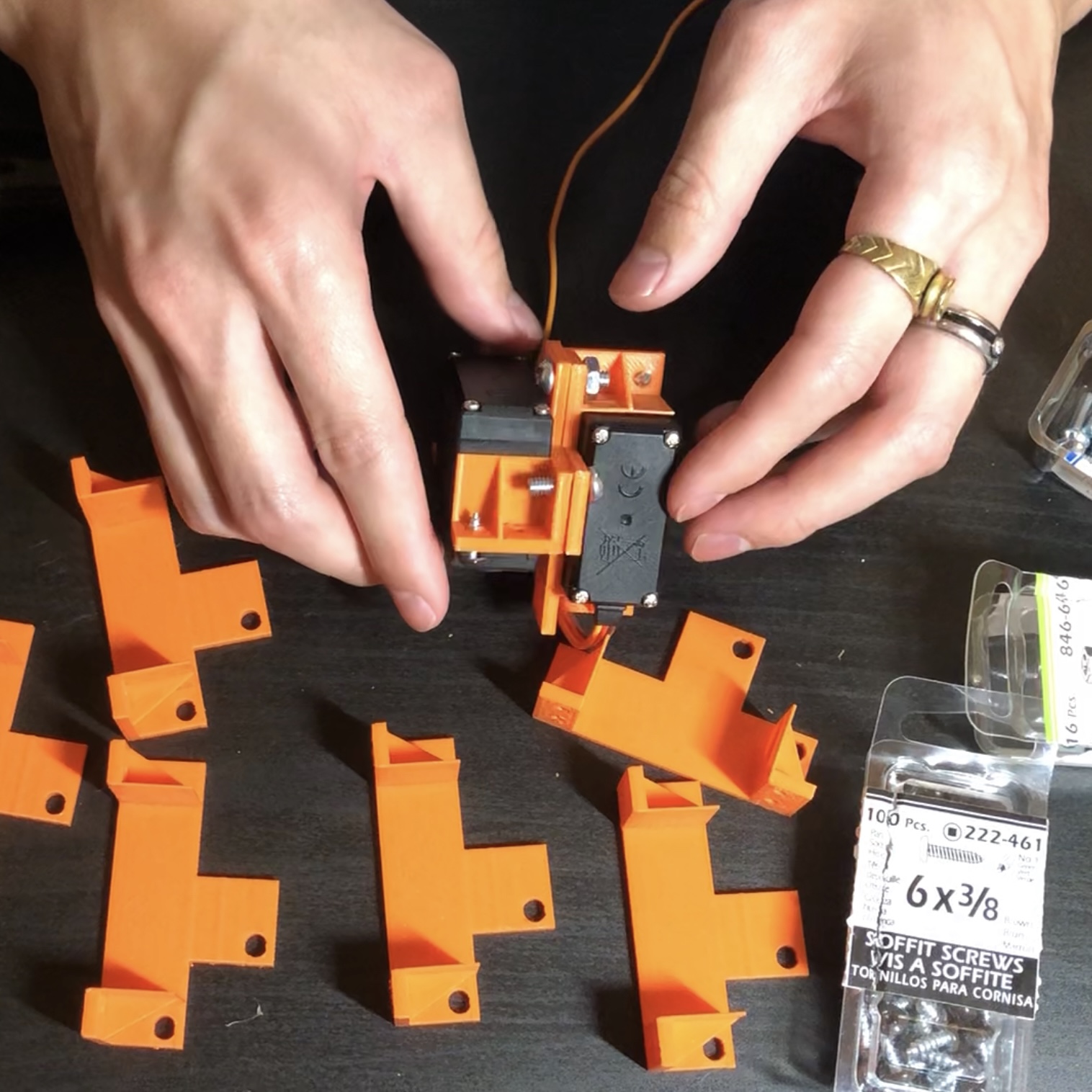

and is fairly straightforward. The program initializes all servo angles

to their closed positions, which causes the legs to retract into a box.

The main function then continuously listens for a message over

Bluetooth, which is triggered by a button press from my phone. I'm using an app called

Arduino Bluetooth Control

which I found for free on the Play Store to communicate with my HC-05

device, though there are plenty of other apps out there that can serve

the same purpose.